Mill Refurbishing and Rebuilding

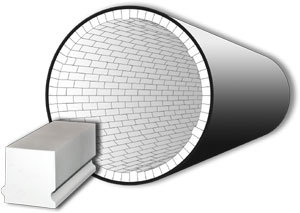

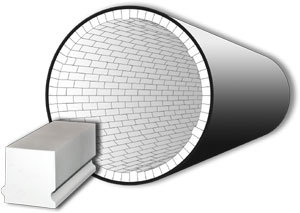

Steel ball mills and ceramic lined mills will eventually need to be refurbished or relined. We can evaluate your mill and do anything from relining with ceramic brick or polyurethane to check and rebuild the bearings and drives components including ring & pinion gears and reducers and motors. If the mill is old and has babbitted bearings we can machine the trunions and replace the old friction bearings with sealed roller bearings. Even old pebble mills with Burrstone linings can be relined with high-alumina brick. We tear out and dispose of the old brick, check the steel shell thickness, repair or replace and thin or corroded section and the install the new brick lining. We use only high quality, fine-grain 90% (or 96%) alumina brick with tongue and groove design. Bricks are secured and grouted with pure Portland cement or two-part epoxy.

Call 630-350-3012 to speak with an expert at Paul O. Abbe® so we can help answer any questions you may have about refurbishing or relining your mill.

See our Size Reduction Options

Benefits of Tumble Milling: 1. HIGH EFFICIENCY – Due to the relatively slow rotational speed but large mass of media, more of the energy goes into millin

More

Benefits of Tumble Milling: HIGH EFFICIENCY – Due to the relatively slow rotational speed but large mass of media, more of the energy goes into milling and less wasted as heat.

More

Slice Mills™ are identical to the Ball Mills and Ceramic Lined Mills in diameter and design The only difference is that they are as little as 12” in length. Since mill diameter dictates performance and mill length only affects capacity, Slice Mills™ are used to develop or test formulations with little concern for scal

More

Our polyurethane mills utilize a proprietary casting method using a fabricated steel mold placed in the mill cylinder creating a 1” void on all sides. Deaerated polyurethane is poured in the space between the mold and cylinder

More

ABBE Jar Rolling Mills are designed to support and rotate our steel and ceramic jars individually or several at a time. The smallest bench top model, can handle 1 or 2 jars. The largest jar roller can have as many as four levels or tiers and from two to five rolls per tier. A "League of their Own" - These are not hobby shop tumblers or light weight rollers found in laboratory supply catalogs. ABBE Jar Rolling Mills are heavy

More

There are almost as many types and sizes of Abbe Milling Jars as there are applications. Abbe Jars are available in a wide range of sizes and materials. Milling jars are small scale version of the ball mills and are typically used in the laboratory or small scale producti

More