Ribbon Blender Mixing Mechanisms

To be cost effective ribbon blenders are loaded to the top of the agitator. Lesser ribbon blender loading will allow proportionately faster mixing. The minimum loading is about 40% of the maximum which is required to keep both the inner and outer ribbon in the product zone. The agitator RPM is designed to provide approximately 300 feet per minute tip speed. The inner and outer ribbons together rotate the mass of material. The outer ribbon moves the solids toward the center of the tough and the inner ribbon moves solids toward the ends.

Mixing time for a fully loaded mixer is typically 15 minutes and is proportional faster for lower loading. A mixer loaded only to the shaft or about 50% may blend in 7 minutes, but of course productivity will suffer ad the batch size has been halved.

The product characteristics that must be considered in selecting a ribbon blender mixing include tapped and untapped bulk densities, particle size and cohesiveness.

For special mixing applications such as powdered metals or friable materials, consider our Rota-Cone® Blenders or CrossMix® Fluidizing Mixers.

For viscous or heavy paste mixing we offer Double-Arm Mixers & Extruders.

Request Price Quote

Click to request a ribbon blender quote online or call 630-350-3012 to speak with an expert at Paul O. Abbe® to help you determine which design and size ball mill would be best for your process.

See our Mixing & Blending Options

Paul O. Abbe designs and manufactures ribbon blenders which are ideal for blending dry, free-flowing solids with bulk densities up to 70 pounds per cubic foot (1.1 g/cc) depending on material characteristics including, particle size, size distribution and particle shape (morphology), angle of repose, cohesiveness and moisture level. Ribbon blender are used for all dry foods products, nutraceuticals, protein powder mixes, dry juice mixes, chemicals, fertilizer, insecticides, colorants, resins and polymers. The moderate shear of the ribbon or paddle naturally breaks down lumps and agglomerates. Ribbon blenders are extremely efficient and economical.

More

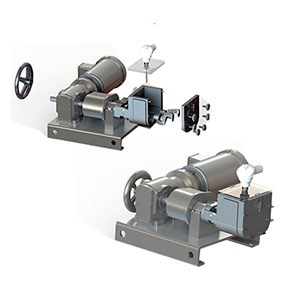

Tumble Blenders include the original ABBE Rota-Cone® Double Cone Blender and the Rota-V Blenders. Tumble blending offers the lowest shear method of mixing friable or delicate solids. The simple double-cone or V-designs provide complete discharge. Because there is no agitator there are no seals and they are easily inspected and cleaned. For these reasons, Tumble Blenders are often employed by the food and pharmaceuticals industrie

More

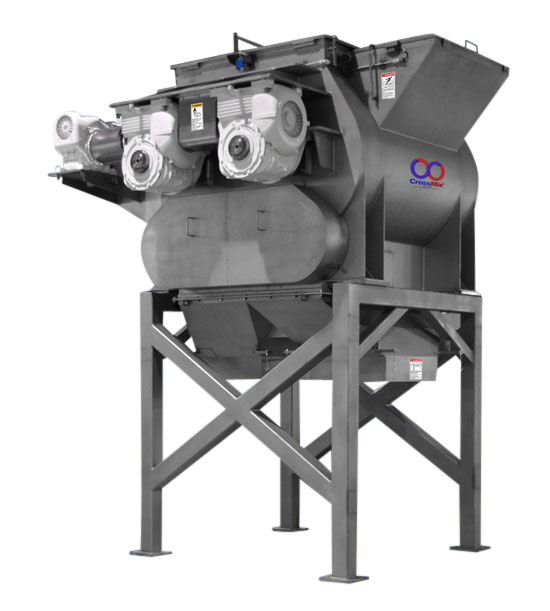

The CrossMix® is a twin-paddle mixer that gently lifts and fluidizes solids in a weightless zone where particles of any size or shape can move freely and mix rapidly. Mixing can be completed in as little as 7 to 20 seconds. The CrossMix® is most beneficial for solids that require very high homogeneity, are fragile such a

More

Aaron Process LNG Laboratory Mixers are available in working capacities from 1/4 gallon to 2 gallon. 1/4 gallon and 1 gallon models are available from stock and furnished with variable speed drives, stainless steel construction and jackets as standard. These units are ideal for research and development, testing new raw materials or scaling up production size batches

More